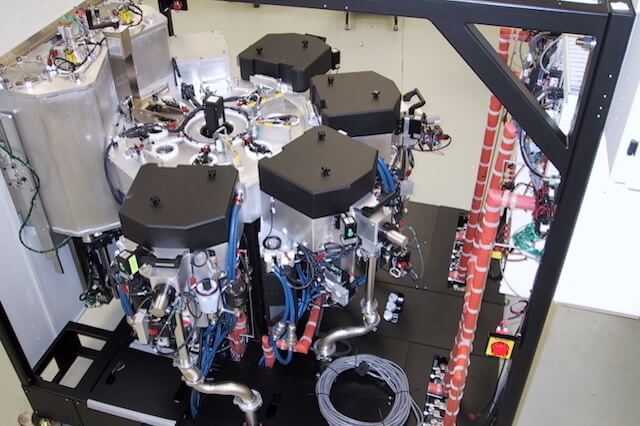

The Centura® is a single-wafer, multi-chamber system that supports processing of wafers ranging in size from 5", 6", or 8". The multi-chamber design allows for individual processes in each of the chambers.

The Centura® I & II platforms may include up to 4 process chambers, and 2 auxiliarry chambers.

The platform improves on the Precision 5000® design by utilizing advanced robotics and independent loadlocks to allow for higher throughput.

The following chamber types can be added to the system:

Lamp Heated CVD - Processes include: SACVD, BWCVD, WCVD, TEOS, Nitride

PE TEOS DxZ - DxZ chamber design for better process control for Plasma Enhanced TEOS applications.

PE Silane DxZ - DxZ chamber design for better process control for Plasma Enhanced Silane based applications.

Gigafill SACVD - Sub-Atmospheric Chemical Vapor Deposition (SACVD) chamber used to deposit BPSG and USG films.

Ultima HDP-CVD - High Density Plasma - Chemical Vapor Deposition (HDP-CVD) is used for deposition and etching simultaneously.

Ultima+ HDP-CVD - High Density Plasma - Chemical Vapor Deposition (HDP-CVD) is used for deposition and etching simultaneously.

Ultima tE HDP-CVD - High Density Plasma - Chemical Vapor Deposition (HDP-CVD) is used for deposition and etching simultaneously.

Tungsten WxZ - Tungsten deposition chamber designed for zero edge exclusion. Available with ceramic heater option.

ALD Tungsten - Atomic Layer Deposition chamber.

WxP Tungsten Etch (HeWeb)- Tungsten etch back chamber with electrostatic chuck or ceramic clampd process kit, depending on process.

Tectra Titanium - Used to deposit low resistivity, high conformity titanium films.

Tectra Tinitride - Used to deposit low resistivity, high conformity titanium films.

ALD Tinitride - Atomic Layer Deposition chamber for depositing TiNitride.

Reactive Preclean+ - Preclean chamber utilizing NF3/He gas to remove native oxide.

Metal Etch DPS - Decoupled Plasma Source (DPS) etch chamber used for Metal etch processes.

Metal Etch DPS+ - Decoupled Plasma Source+ (DPS+) etch chamber used for Metal etch processes.

Poly Etch DPS - Decoupled Plasma Source (DPS) etch chamber used for Polysilicon etch processes.

Poly Etch DPS+ - Decoupled Plasma Source+ (DPS+) etch chamber used for Polysilicon etch processes.

Poly Etch Deep Trench (DT) - Description Here.

ASP - Advanced Strip Passivation (ASP) chamber used to remove photo resist and passivate the wafer.

ASP+ - Advanced Strip Passivation+ (ASP+) chamber used to remove photo resist and passivate the wafer.

Oxide Super-E - Dielectric etch chamber.

Oxide eMxP+ - Dielectric etch chamber.

Oxide MxP+ - Dielectric etch chamber.

Oxide eMax - Dielectric etch chamber.

IPS Dielectric Etch - Inductively Coupled Parallel Plate Semiconductor Dielectric Etch (IPS) chamber.

Poly Etch MxP - Reactive Ion Etch chamber used for etching Polysilicon films.

Poly Etch MxP+ - Reactive Ion Etch chamber used for etching Polysilicon films.

R2 Metal Etch - Reactive Ion Etch chamber used for etching Metal films.

Metal Etch MxP - Reactive Ion Etch chamber used for etching Metal films.

Mark II Etch - Used for Sputter etch or Reactive Ion Etching.

Orienter - Findes center of the wafer for proper placement. Notch/flat aligns the wafer.

Single Slot Cooldown - Utilizes a water cooled pedestal to cool the wafer when placed in the chamber. Wafers do not contact the pedestal.

Single Slot Contact Cooldown - Utilizes a water cooled pedestal to cool the wafer when placed in the chamber. Wafers contact the pedestal, allowing for faster cooling, and higher throughput.

Multi-Slot Cooldown - Cools up to eight wafers simultaneously in a water cooled cassette elevator.